In highly regulated industries where precision, traceability, and compliance are non-negotiable, calibration is not just a routine task—it is a critical function that ensures data integrity, product quality, and regulatory adherence. At International Process Solutions, we have worked with countless organizations to identify and correct calibration issues before they escalate into costly compliance failures. Understanding

In precision-driven industries, accuracy is not optional—it is foundational. At International Process Solutions, we understand that routine calibration is the invisible safeguard behind compliant operations, reliable data, and consistent product quality. When equipment is not calibrated regularly, risks multiply rapidly across operational, financial, regulatory, and reputational dimensions. Below, we outline the concrete risks organizations face

In highly regulated industries such as pharmaceuticals, biotechnology, medical devices, food manufacturing, and research laboratories, precision is non-negotiable. At International Process Solutions, we deliver regulatory-compliant pipette calibration services designed to protect data integrity, ensure laboratory accuracy, and maintain full alignment with industry standards. Every microliter matters. Even the smallest deviation in volume measurement can compromise

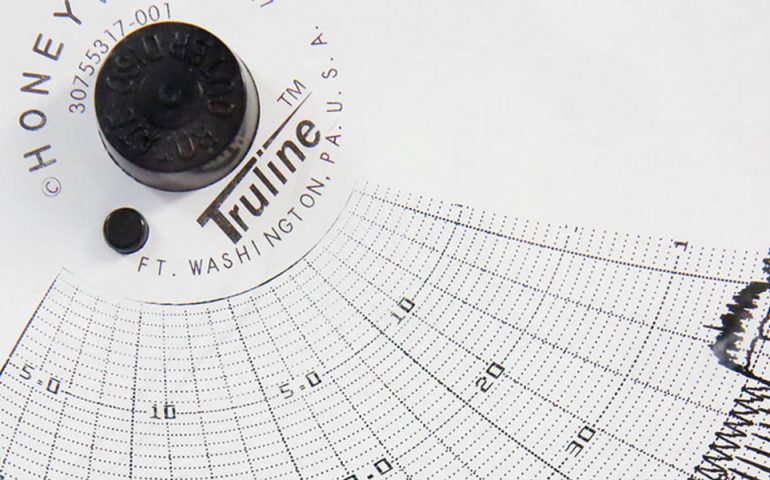

Calibration is the backbone of accuracy, compliance, safety, and operational efficiency across regulated and industrial environments. From pharmaceutical manufacturing to energy production, the question we are most often asked is simple yet critical: can calibration be performed on-site, or must instruments be sent to a laboratory? At International Process Solutions, we address this question with

In the pharmaceutical industry, precision is not optional—it is foundational to safety, compliance, and product integrity. We understand that every measurement, every data point, and every controlled parameter directly impacts patient outcomes, regulatory standing, and operational excellence. At International Process Solutions (IPS), we deliver comprehensive pharmaceutical calibration services engineered to support regulated environments where accuracy,

In regulated industries where sterility, safety, and precision are non-negotiable, autoclave calibration and validation are foundational requirements. At International Process Solutions, we deliver comprehensive, compliant, and audit-ready autoclave calibration and validation services designed to meet the most stringent regulatory expectations. We support pharmaceutical, biotechnology, medical device, laboratory, and life science organizations that rely on autoclaves

In regulated laboratories, manufacturing facilities, and research environments, temperature-controlled storage is the backbone of reliable science and compliant operations. At International Process Solutions, we understand that freezers are not simply storage units—they are critical safeguards for valuable samples, sensitive materials, and regulatory trust. Freezer calibration ensures that these safeguards perform exactly as intended, every hour

In modern laboratories, centrifuges are foundational instruments that directly influence the accuracy, reliability, and repeatability of test results. At International Process Solutions, we understand that centrifuge performance is not optional—it is mission-critical. Centrifuge calibration ensures that every rotation, every force, and every separation step aligns precisely with validated specifications. Without proper calibration, even the most

At International Process Solutions, we understand that precision, traceability, and documented accuracy are not optional in regulated industries—they are foundational. NIST-traceable calibration plays a decisive role in maintaining compliance with Good Manufacturing Practices (GMP) and Good Laboratory Practices (GLP). We deliver calibration solutions designed to meet the strictest regulatory expectations while supporting operational excellence, audit

As we step into a new year, organizations across regulated and precision-driven industries face a critical responsibility: ensuring that all equipment is calibrated properly and performing to exact specifications. At International Process Solutions, we take a proactive, compliance-focused approach to calibration that safeguards accuracy, reliability, and operational continuity. A new year is not simply a

Recent Comments