Process Meter Calibration Quick Links

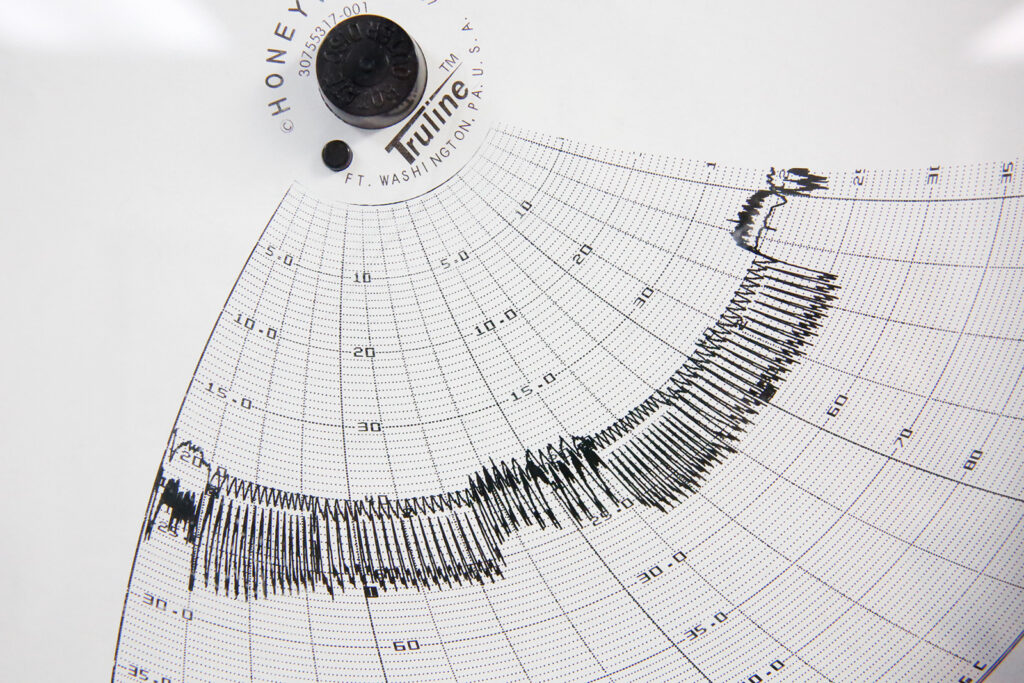

Process meter calibration is a critical component of any industrial process. It is the process of verifying and adjusting the accuracy of process meters in order to ensure that they are functioning optimally. Process meters are used to measure and monitor a variety of processes including temperature, pressure, flow, level, and pH. Calibration ensures that these meters provide accurate and reliable readings that meet all required standards.

Proper calibration of process meters is essential for ensuring that industrial processes run smoothly and efficiently. Inaccurate or unreliable measurements can result in incorrect conclusions being drawn, which can lead to costly mistakes and downtime. Calibrated process meters provide accurate measurements that enable operators to make informed decisions that lead to better process control, improved safety, and increased productivity.

Email, call, fax, or fill out our form – whatever works best for you. We’re here to serve, and to help. Reach out now – we’d love nothing more than to connect.

Southern California Calibration Services

tel: 310-432-0665

Northern California Calibration Services

tel: 650-595-7890

fax: 650-595-7899