International Process Solutions (IPS) is proud to announce that we now offer ISO 17025 accredited calibration services throughout Southern and Northern California. Our services cover a wide range of parameters, including electrical, thermodynamic, dimensional, and time/frequency measurements, ensuring that our clients receive the highest standard of calibration services available in the industry. What is ISO

When it comes to ensuring the accuracy and reliability of your equipment, selecting the right calibration service provider is crucial. Accurate calibration not only guarantees compliance with industry standards but also enhances the longevity and performance of your instruments. Here, we outline the essential considerations and steps to take when choosing a calibration service provider

In today’s competitive manufacturing landscape, precision is paramount. As the baby boomer workforce retires, a wealth of technical expertise is vanishing, creating significant challenges for industries reliant on meticulous calibration processes. Ensuring accurate calibration is not merely a procedural necessity; it is a critical component that directly impacts product quality, safety, and profitability. The Consequences

In the fast-paced and highly competitive world of modern industry, ensuring the accuracy and reliability of your equipment is paramount. Calibration plays a crucial role in maintaining the precision and functionality of various instruments and machinery. The frequency with which you should calibrate your equipment can vary based on numerous factors. In this article, we

Humidity calibration is a critical component across various industries, ensuring that environmental conditions remain within specified parameters. Precise humidity control is paramount in sectors such as pharmaceuticals, electronics, food processing, and agriculture. Each of these industries relies heavily on accurate humidity measurements to maintain product quality, comply with regulatory standards, and optimize operational efficiency. The

Properly maintaining calibration records is essential for ensuring the accuracy and reliability of measuring instruments in any industry. In this article, we outline the best practices for keeping thorough, organized, and compliant calibration records. This guide will help you optimize your calibration processes, enhance quality control, and meet regulatory requirements. Importance of Accurate Calibration Records

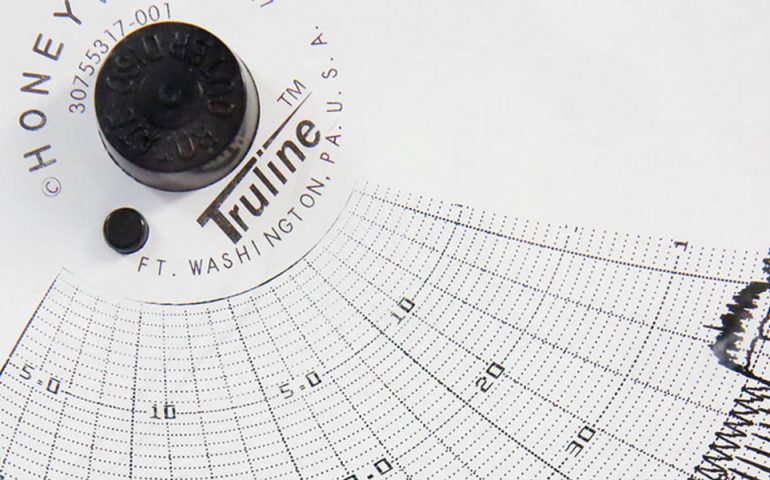

Calibration Ensuring Precision Calibration plays a pivotal role in quality control processes across various industries. At its core, calibration involves comparing measurements of an instrument or device against a known and traceable standard. By ensuring that instruments are accurate and reliable, calibration guarantees the precision and consistency of results, thereby upholding quality standards. Maintaining Accuracy

In the meticulous world of precision, maintaining accurate calibration records is paramount. Properly managed records ensure compliance, enhance reliability, and support traceability in various industries. Here, we delve into the best practices for maintaining calibration records to ensure optimal performance and adherence to stringent standards. Understanding the Importance of Calibration Records Calibration records serve as

Recent Comments