In today’s world, where precision and accuracy are paramount, the need for regular calibration services has never been more critical. Whether in manufacturing, healthcare, or any other industry where measurements are essential, maintaining the accuracy of your equipment is key to ensuring consistent quality and safety. This article delves into the significance of regular calibration, illustrating

In the phamaceutical industry, where precision and accuracy are paramount, calibration services play an essential role in maintaining the integrity of critical processes. The stringent regulations governing pharmaceutical production demand that every instrument and piece of equipment used in manufacturing, testing, and quality control is meticulously calibrated to ensure consistent and reliable performance. Pharmaceutical calibration

Calibration plays a crucial role in maintaining the accuracy and reliability of measurement instruments. However, it is essential to recognize that environmental conditions can have a profound impact on the effectiveness of calibration processes. Whether in laboratories, manufacturing facilities, or field operations, the environment in which calibration occurs can directly affect the performance of the instruments

Introduction to Pipette Calibration In the world of laboratory research and diagnostics, pipettes are indispensable tools used for measuring and transferring small volumes of liquids with high precision. However, to ensure the accuracy and reliability of your results, pipette calibration is crucial. Calibration is the process of verifying and adjusting the pipette to ensure it delivers

Digital multimeters are indispensable tools for technicians, engineers, and hobbyists alike. They offer a range of functionalities, such as measuring voltage, current, and resistance, making them versatile for various applications. However, to ensure their accuracy and reliability, calibration is essential. In this comprehensive guide, we will delve into the fundamental aspects of digital multimeter calibration, providing

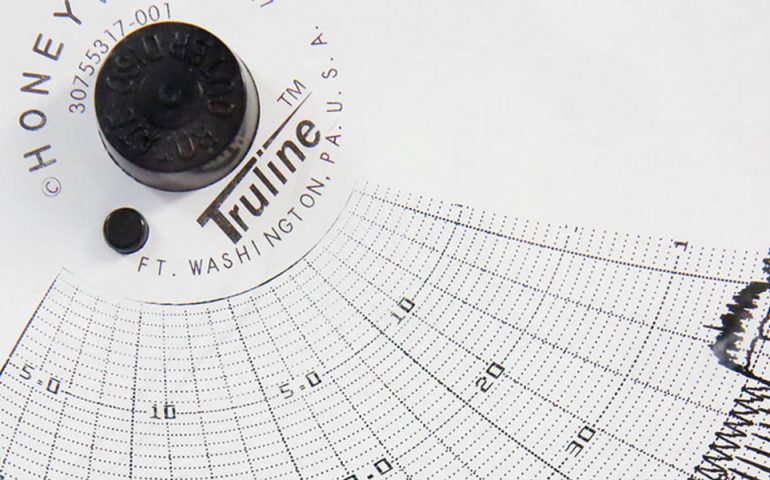

Accurate humidity calibration is crucial for industries where precise environmental conditions are necessary, such as pharmaceuticals, HVAC systems, and manufacturing. At the heart of effective humidity calibration lies a suite of essential equipment designed to ensure precision and reliability. This article delves into the critical tools and technologies that make humidity calibration not only possible

International Process Solutions (IPS) is proud to announce that we now offer ISO 17025 accredited calibration services throughout Southern and Northern California. Our services cover a wide range of parameters, including electrical, thermodynamic, dimensional, and time/frequency measurements, ensuring that our clients receive the highest standard of calibration services available in the industry. What is ISO

When it comes to ensuring the accuracy and reliability of your equipment, selecting the right calibration service provider is crucial. Accurate calibration not only guarantees compliance with industry standards but also enhances the longevity and performance of your instruments. Here, we outline the essential considerations and steps to take when choosing a calibration service provider

In today’s competitive manufacturing landscape, precision is paramount. As the baby boomer workforce retires, a wealth of technical expertise is vanishing, creating significant challenges for industries reliant on meticulous calibration processes. Ensuring accurate calibration is not merely a procedural necessity; it is a critical component that directly impacts product quality, safety, and profitability. The Consequences

In the fast-paced and highly competitive world of modern industry, ensuring the accuracy and reliability of your equipment is paramount. Calibration plays a crucial role in maintaining the precision and functionality of various instruments and machinery. The frequency with which you should calibrate your equipment can vary based on numerous factors. In this article, we

Recent Comments