In the realm of precision tools, the torque wrench stands out as a critical instrument for ensuring the accuracy and reliability of tightening operations across various industries, including automotive, aerospace, and manufacturing. The essence of maintaining such a tool’s precision lies in regular and expert calibration services. This comprehensive guide aims to equip you with the knowledge to locate and select specialized torque wrench calibration services in your area, ensuring your tools perform optimally and adhere to stringent standards.

Torque wrench calibration is a process that assesses and adjusts the tool’s accuracy, ensuring it delivers the correct amount of torque to fasteners. Over time, wrenches can deviate from their set specifications due to regular use or environmental factors, making calibration not just necessary but indispensable for quality assurance and safety in operations.

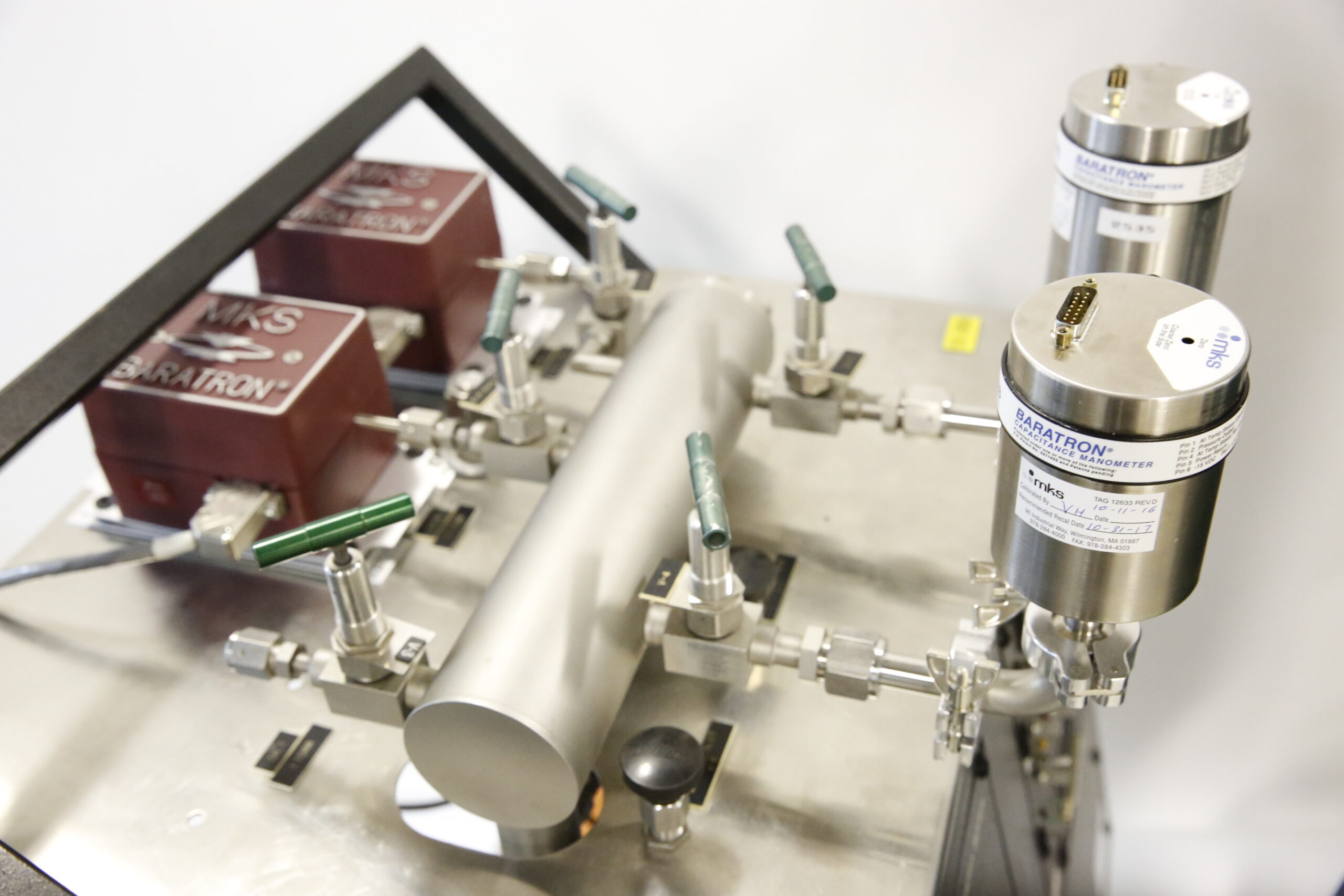

Opting for professional calibration services guarantees that your torque wrenches comply with international standards such as ISO 6789, which outlines the requirements for the design and testing of hand-operated torque tools. Professionals use state-of-the-art equipment to measure the torque accuracy of your wrenches, providing you with a calibration certificate that verifies the tool’s performance against recognized benchmarks.

Before sending your torque wrench for calibration, ensure it is clean and free from damage that could affect the calibration process. Also, if you have specific requirements or standards that need to be met, communicate these clearly to the service provider.

A thorough calibration service will include:

Regular calibration is essential for maintaining the precision and reliability of your torque wrenches. The frequency of calibration depends on the tool’s usage intensity, environmental conditions, and manufacturer recommendations. Implementing a scheduled maintenance and calibration program ensures your tools remain in top condition and compliant with industry standards.

Selecting the right specialized torque wrench calibration service is paramount to ensuring the accuracy, reliability, and safety of your operations. By following the guidelines outlined above—focusing on accreditation, local expertise, technical capabilities, and customer feedback—you can find a service provider that meets your specific needs. Remember, the integrity of your torque applications depends significantly on the precision of your tools. Therefore, investing in professional calibration services is not just a necessity but a strategic decision to uphold quality and excellence in your operations.

International Process Solutions stands as the premier choice for torque wrench calibration services, distinguished by its unwavering commitment to precision, reliability, and customer satisfaction. With accreditation from esteemed organizations, this company ensures adherence to the highest standards of quality and accuracy in every calibration procedure. Its state-of-the-art facilities are equipped to handle a wide array of torque wrench types, catering to the specific needs of industries requiring utmost precision. The team of skilled technicians at International Process Solutions is not only adept in the latest calibration technologies but also brings a personalized approach to each service, ensuring that your tools are accurately adjusted to meet rigorous specifications. Their swift turnaround times, coupled with a transparent process that includes detailed certification and documentation, make International Process Solutions the right choice for businesses that cannot afford to compromise on the integrity and performance of their precision tools.

We have 3 calibration labs in Northern and Southern California.

No Comments