In the pharmaceutical industry, maintaining strict calibration compliance is essential for ensuring product quality, patient safety, and regulatory approval. Precision in calibration directly impacts the accuracy of laboratory instruments, the reliability of test results, and the efficiency of manufacturing processes. In this comprehensive guide, we outline the key principles, regulatory expectations, and best practices for achieving full calibration compliance in the pharmaceutical sector.

The Importance of Calibration in Pharmaceuticals

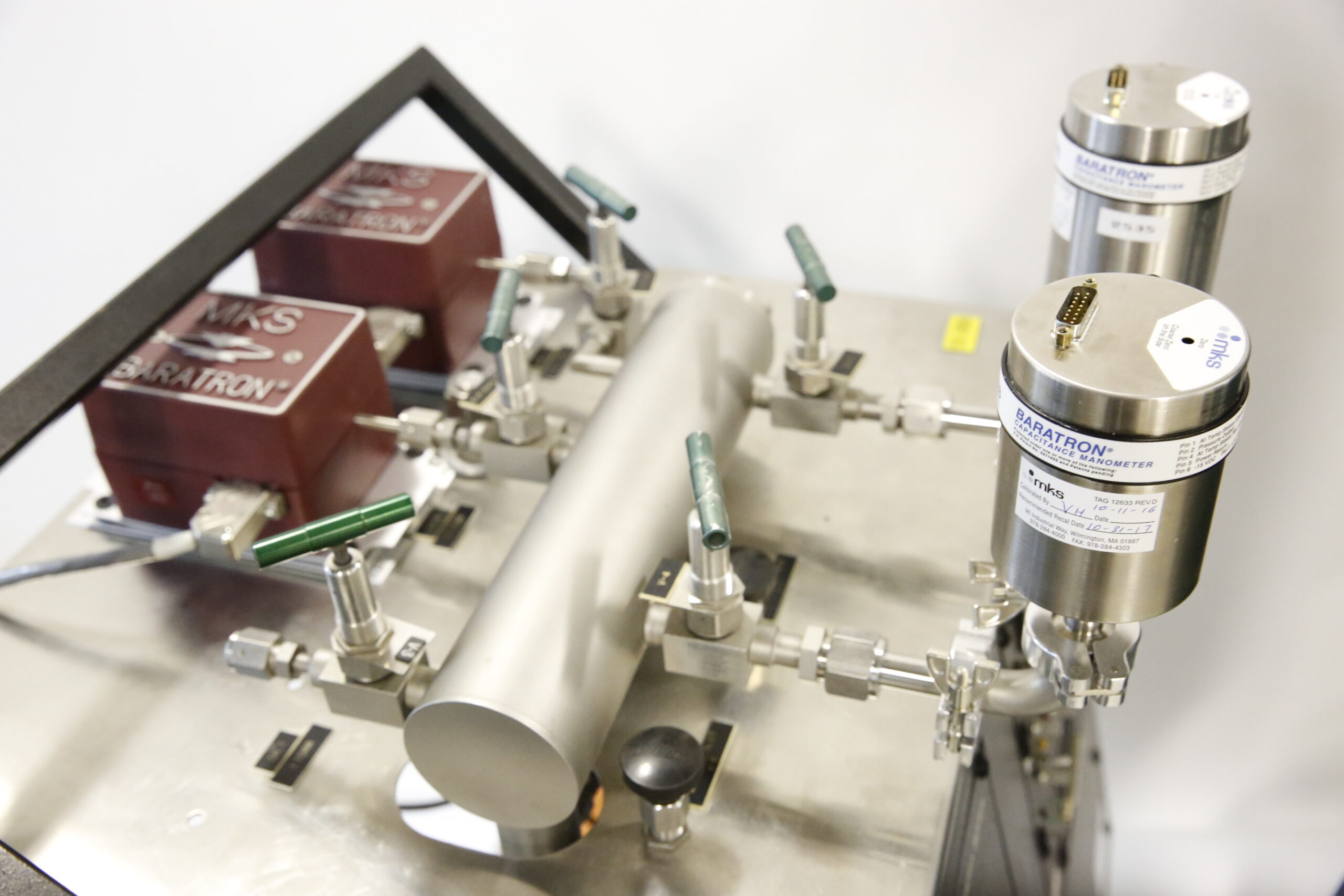

Calibration in the pharmaceutical industry ensures that measurement equipment performs within defined tolerances. Whether it is balances, pipettes, temperature probes, or high-performance liquid chromatography (HPLC) systems, every instrument must provide consistent and reproducible results. Non-compliance can lead to:

- Batch failures and costly recalls

- Compromised patient safety

- Regulatory fines and warnings

- Delays in product release

The pharmaceutical industry operates under a zero-defect philosophy, meaning even the smallest measurement error can have large consequences.

Regulatory Standards Governing Calibration Compliance

Pharmaceutical companies must adhere to global regulatory requirements to ensure calibration compliance. These standards mandate strict controls over how instruments are calibrated, documented, and maintained. Key regulatory guidelines include:

- FDA 21 CFR Part 11 – Requires proper calibration documentation and electronic recordkeeping with audit trails.

- GxP (Good Practice guidelines) – Covers Good Manufacturing Practice (GMP), Good Laboratory Practice (GLP), and Good Clinical Practice (GCP), emphasizing equipment qualification and calibration.

- ICH Q10 – Focuses on the pharmaceutical quality system, including calibration as part of risk management.

- ISO 17025 – Specifies requirements for testing and calibration laboratories, ensuring competence and traceability.

- USP <41> and <1251> – Provide detailed standards for weighing equipment calibration and verification.

Meeting these standards not only ensures compliance but also builds confidence in the reliability of test results.

Calibration vs. Verification: Understanding the Difference

Many pharmaceutical companies confuse calibration with verification. While both are critical, they serve different purposes:

- Calibration: Adjusting an instrument to ensure accuracy against a recognized standard.

- Verification: Checking whether an instrument continues to meet pre-defined acceptance criteria.

A robust compliance program must incorporate both, ensuring instruments not only perform correctly after calibration but remain within tolerance during everyday use.

Risk-Based Calibration Approach

A risk-based calibration program ensures resources are directed where they are needed most. Instruments can be classified into three categories:

- Critical Instruments – Directly impact product quality (balances, pH meters, HPLC systems). These require frequent calibration.

- Non-Critical Instruments – Indirectly affect processes (thermometers in non-controlled storage areas). Calibrated less frequently.

- Auxiliary Instruments – Used for monitoring only. Verification may be sufficient.

This classification reduces downtime, optimizes costs, and ensures compliance without over-calibration.

Calibration Lifecycle in the Pharmaceutical Industry

A proper calibration compliance program follows a structured lifecycle:

- Instrument Qualification (IQ, OQ, PQ)

- IQ: Installation Qualification – ensuring correct setup.

- OQ: Operational Qualification – verifying performance against specifications.

- PQ: Performance Qualification – ensuring consistent performance under real conditions.

- Calibration Scheduling

- Defined based on manufacturer recommendations, historical data, and risk assessment.

- Preventive calibration is preferred over reactive measures.

- Calibration Execution

- Carried out using certified reference standards with traceability to NIST or other recognized bodies.

- Performed by trained professionals with validated procedures.

- Documentation and Recordkeeping

- Records must include instrument ID, calibration date, standards used, results, and technician details.

- Compliance with FDA 21 CFR Part 11 requires secure electronic documentation with audit trails.

- Deviation Management

- Out-of-tolerance results must be investigated promptly.

- Impact assessment on product batches is mandatory.

- Corrective and preventive actions (CAPA) must be documented.

The Role of Traceability in Calibration Compliance

Calibration in pharmaceuticals must be traceable to national or international standards. This ensures results are universally recognized and comparable across laboratories. Traceability provides:

- Confidence in measurement accuracy

- Consistency across global facilities

- Regulatory acceptance

Without traceability, even precise calibration results may not meet compliance standards.

Common Calibration Challenges in Pharmaceuticals

Despite strict requirements, pharmaceutical companies often face challenges such as:

- Instrument Drift – Gradual deviation of instrument accuracy over time.

- Improper Scheduling – Overdue calibrations leading to compliance risks.

- Data Integrity Issues – Missing documentation or incomplete audit trails.

- Limited Resources – Insufficient trained staff or inadequate equipment.

Implementing a calibration management system (CMS) can overcome these challenges by automating scheduling, tracking, and reporting.

Calibration Documentation Requirements

Accurate documentation is the backbone of calibration compliance. Records must include:

- Unique equipment identification number

- Calibration procedure reference

- Standards and reference materials used

- Pre- and post-calibration readings

- Pass/fail results

- Name and signature of the technician

- Next due date

Incomplete documentation is a common cause of FDA warning letters. A paperless calibration system with electronic signatures ensures efficiency and compliance.

Best Practices for Achieving Calibration Compliance

To maintain compliance and efficiency, pharmaceutical companies should adopt these best practices:

- Implement a centralized calibration management system

- Use only accredited calibration service providers (ISO 17025 certified)

- Train staff regularly on calibration procedures and data integrity

- Perform internal audits to verify compliance with regulatory standards

- Establish clear SOPs for calibration, verification, and deviation management

- Review calibration trends to predict and prevent instrument failures

The Future of Calibration in the Pharmaceutical Industry

Advancements in digital calibration technologies and automation are transforming compliance programs. Cloud-based systems, IoT-enabled devices, and AI-powered analytics allow pharmaceutical companies to:

- Predict calibration needs based on real-time data

- Reduce human error through automated processes

- Enhance data integrity with secure electronic records

- Streamline global compliance across multiple facilities

Companies embracing digital calibration solutions are better positioned to maintain compliance, reduce costs, and improve overall efficiency.

Conclusion

Calibration compliance in the pharmaceutical industry is more than a regulatory requirement—it is a foundation for quality assurance and patient safety. By implementing a structured, risk-based, and well-documented calibration program, pharmaceutical companies can ensure consistent product quality, avoid costly compliance issues, and maintain trust with regulators and patients alike.

Adopting best practices, leveraging advanced technology, and ensuring traceability are essential steps toward maintaining full calibration compliance in today’s highly regulated pharmaceutical landscape.