Avoid downtime, defects, and liability with proper torque calibration—before it’s too late. When companies skip torque wrench calibration, they’re not saving money—they’re silently setting the stage for equipment failure, rework, safety risks, and expensive liability issues. Torque tools are precision instruments, and even slight deviation in applied torque can lead to catastrophic outcomes. This guide

Why Choosing the Right Calibration Provider Matters Whether you run a pharmaceutical lab, a biotech facility, a manufacturing plant, or a medical device operation, your equipment accuracy drives everything. When calibration is delayed, incomplete, or done incorrectly, the fallout can be brutal: Failed audits Production shutdowns Equipment drift and out-of-tolerance issues Regulatory violations (FDA, ISO,

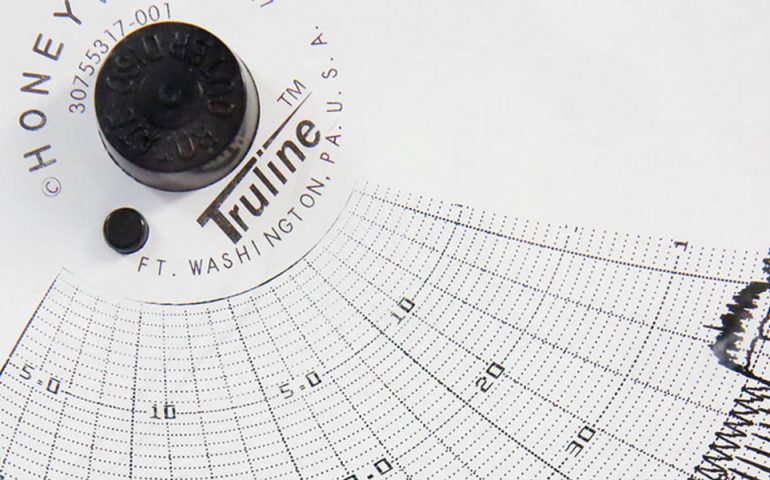

When precision is non-negotiable, torque wrench calibration becomes the backbone of accuracy for laboratories, manufacturing facilities, aerospace teams, automotive shops, and medical device producers. At International Process Solutions (IPS), we deliver meticulously accurate torque wrench calibration services designed to uphold the strictest quality and compliance standards. Our commitment to excellence ensures that every torque tool

Relocating a pharmaceutical lab involves much more than boxing up equipment and loading trucks. With regulatory compliance, temperature requirements, chain-of-custody documentation, and complex instrumentation in the mix, this type of move demands strategic planning and specialized support. Below, we break down exactly what goes into a successful lab relocation—along with how International Process Solutions (IPS)

In the competitive landscape of modern industry, precision and reliability are more than operational ideals—they are strategic imperatives. At International Process Solutions, we understand that the ROI of calibration extends far beyond simple compliance. Accurate instrumentation and well-maintained measurement systems deliver measurable financial benefits, operational efficiency, and enhanced product quality. Companies that underestimate the power

Precision is the foundation of reliable results in any laboratory, manufacturing, or industrial environment. When equipment falls out of calibration, it doesn’t just affect accuracy—it impacts quality control, compliance, and safety. Recognizing the signs that your equipment needs immediate recalibration can prevent costly downtime, product recalls, and potential regulatory violations. At International Process Solutions, we

In today’s precision-driven industries, equipment calibration is more than a compliance box—it’s a cornerstone of accuracy, reliability, and safety. Yet, many facilities underestimate the true impact of neglecting regular calibration. At International Process Solutions (IPS), we’ve seen firsthand how skipping calibration not only disrupts operations but also leads to serious financial, regulatory, and reputational consequences.

In the oil and gas industry, where accuracy, efficiency, and safety are paramount, ultrasonic flow calibration has become a cornerstone of precision measurement. As global demand continues to rise and environmental regulations tighten, companies must ensure that every drop of product is measured accurately — whether it’s crude oil, natural gas, or refined hydrocarbons. Ultrasonic

When precision matters most, calibration services are the silent force behind accuracy, reliability, and compliance in every laboratory, manufacturing plant, and testing facility. At International Process Solutions, we specialize in comprehensive calibration services designed to help organizations across industries meet stringent regulatory requirements while maintaining the highest standards of measurement integrity. What Are Calibration Services

Recent Comments