Have you ever questioned whether your centrifuge is giving trustworthy results? An uncalibrated centrifuge can lead to inaccurate test data, regulatory non-compliance, costly downtime, and even safety hazards. In industries where precision is non-negotiable—such as clinical diagnostics, pharmaceuticals, and biotechnology—these risks can’t be ignored. Quick Answer: What is Centrifuge Calibration? Centrifuge calibration is the process

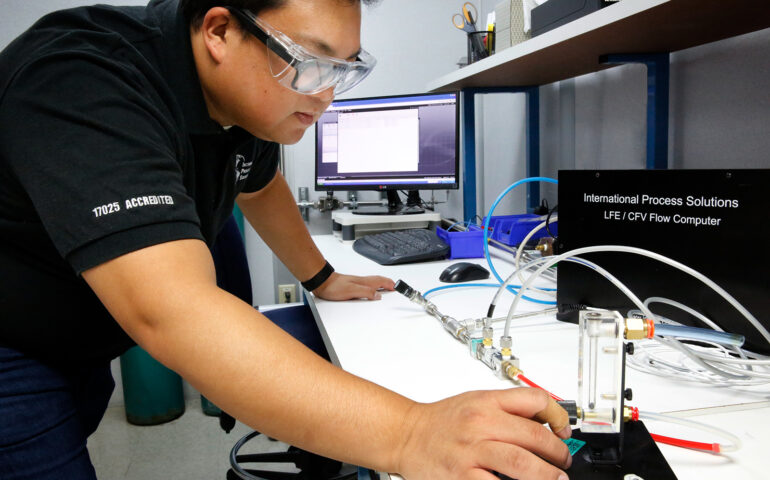

Ensuring precision in laboratory testing is fundamental to maintaining data integrity, safety, and compliance. At International Process Solutions (IPS), we specialize in pipette calibration standards that guarantee the accuracy and reliability of liquid handling instruments across industries. Our commitment to ISO 17025 accreditation, rigorous testing protocols, and traceable calibration methods places us at the forefront

San Carlos, California – 9/18 – International Process Solutions (IPS), a leading provider of precision calibration and laboratory solutions, is proud to announce that it has achieved ISO 17025 accreditation for its pipette calibration services. This milestone reflects IPS’s unwavering commitment to quality, accuracy, and reliability in laboratory instrumentation, further solidifying its position as an

In the pharmaceutical industry, maintaining strict calibration compliance is essential for ensuring product quality, patient safety, and regulatory approval. Precision in calibration directly impacts the accuracy of laboratory instruments, the reliability of test results, and the efficiency of manufacturing processes. In this comprehensive guide, we outline the key principles, regulatory expectations, and best practices for

Ensuring accuracy and precision in laboratory work relies heavily on the proper calibration of pipettes. A well-calibrated pipette guarantees reliable results, minimizes costly errors, and supports compliance with industry standards. At our organization, we place strong emphasis on adhering to best practices for pipette calibration, so laboratories can consistently achieve the highest level of performance

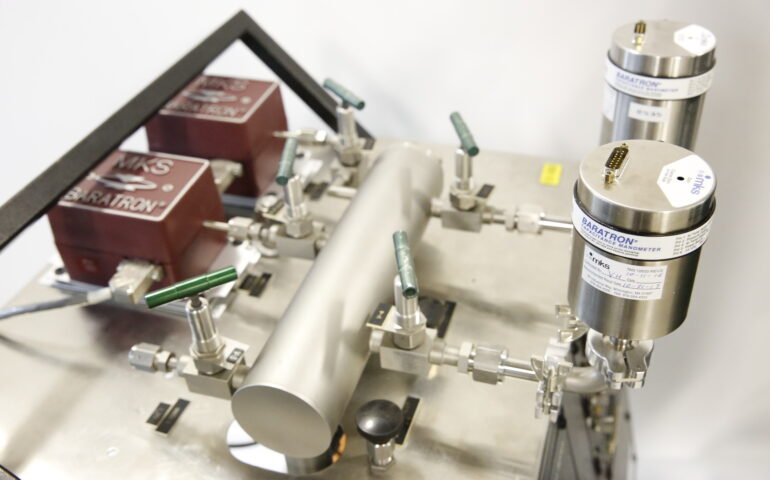

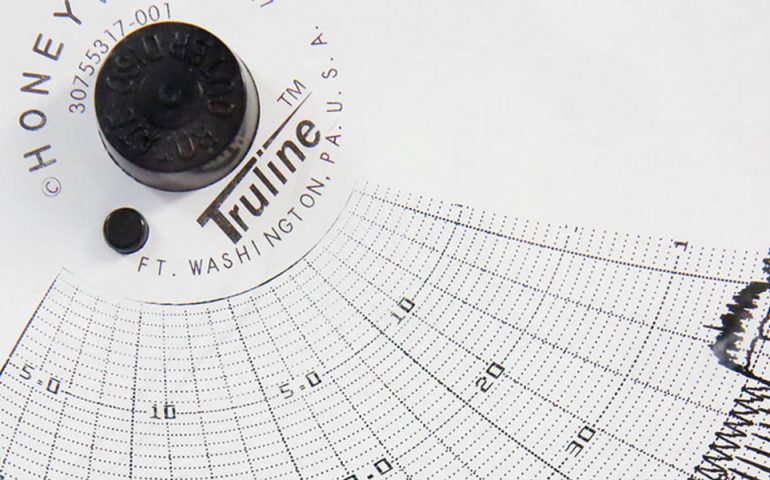

Proper calibration of industrial equipment and instruments is a critical component of operational efficiency. At International Process Solutions, we prioritize precision and accuracy, understanding that consistent calibration directly reduces costs, minimizes downtime, and extends the lifespan of critical machinery. This article explores the detailed strategies and methodologies for implementing an effective calibration program that ensures

Proper equipment calibration is essential for ensuring accuracy, compliance, and operational efficiency across industries. At International Process Solutions, we specialize in providing professional calibration services with quick turnaround times and precision standards that exceed expectations. To help companies achieve the most reliable results, we have created this step-by-step guide to preparing equipment for calibration. By

At International Process Solutions, we understand that precision and reliability are the foundation of every successful operation. Whether you work in pharmaceuticals, aerospace, medical devices, food production, or energy, the question of how often instruments should be calibrated is not one to take lightly. The accuracy of your instruments directly influences product quality, compliance, safety,

In today’s highly competitive manufacturing landscape, precision and reliability are no longer optional—they are the foundation of success. At International Process Solutions, we have witnessed firsthand the consequences of skipping regular calibration: increased downtime, costly product recalls, diminished customer trust, and serious compliance violations. Regular calibration is not merely a maintenance task; it is a

Recent Comments