At International Process Solutions, we understand the crucial role that accurate instrument calibration plays in ensuring reliable and precise measurements for your business. One significant aspect that should never be overlooked is the identification of the make and model of the instrument being calibrated. In this article, we will delve into the importance of make and model information and its impact on the calibration process.

The header information of an instrument calibration certificate holds utmost importance as it provides essential details about the instrument itself. This includes the manufacturer, model, description, serial number, and ID number. While these details may seem like basic information, they play a vital role in conveying the specific instrument being calibrated accurately.

Certain circumstances may arise where an instrument does not have a visible or legible model number. This can occur if the manufacturer has not attached or inscribed a model number on the instrument, or if the model number has been worn off or removed. However, the absence of a readily available model number does not mean that the instrument is without one.

If the original equipment manufacturer (OEM) is still in operation, determining the correct model number should be relatively straightforward. Contacting the OEM or referring to their documentation can help identify the model associated with the instrument in question. Similarly, if the OEM has been acquired by another company, they may also assist in determining the correct model number.

Unfortunately, there may be cases where it becomes impossible to ascertain the model number, despite exploring all possible avenues. This creates a challenging situation because the performance specifications of the instrument, such as accuracy, linearity, repeatability, hysteresis, etc., are intricately linked to the specific model number. Without the model number, it becomes difficult to accurately determine the specifications against which the instrument should be calibrated.

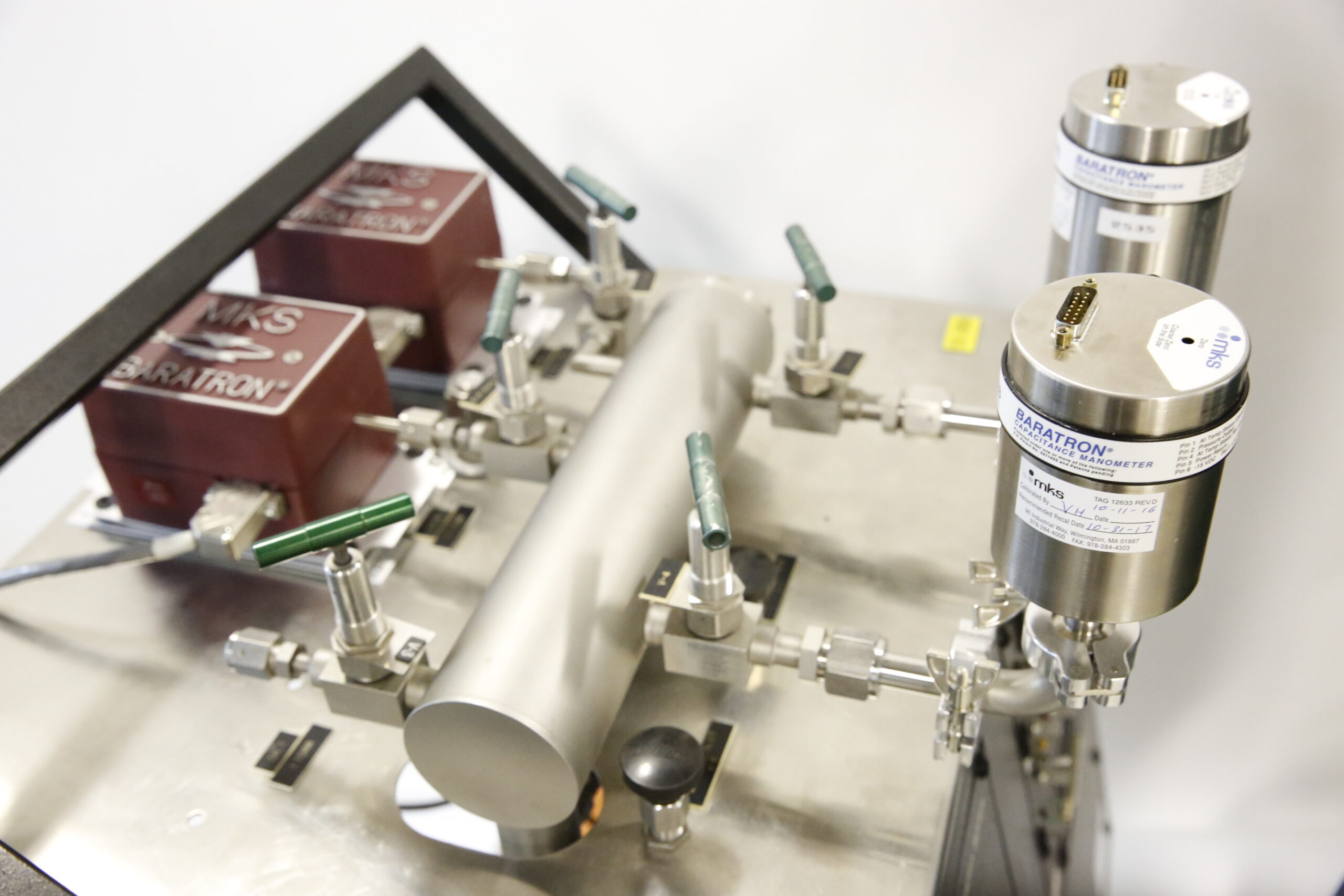

Several types of instruments commonly face challenges in determining the model number. These may include hand tools (e.g., plugs, rings, pins, micrometers, calipers, rulers, etc.), weights, gage blocks, pressure gauges, and more. For such instruments, arbitrarily assigning tolerances during calibration can have significant implications for your quality system.

If calibration labs assign tolerances without accurate model information, the measured tolerances may not align with the criteria you use to accept or reject products. This can lead to a loss of quality control, potentially impacting your manufacturing or testing processes adversely.

To maintain control over your quality system in the absence of a known model and specifications, it is crucial for you, as the equipment owner, to determine the tolerances required by your process. These tolerances should be used to determine the acceptable tolerances applicable to the instrument being calibrated. Alternatively, replacing the “Unknown” instrument with one that has a known model and performance specifications can effectively eliminate the challenge from your system.

When working with International Process Solutions, in cases where the model (and thus specifications) cannot be determined, we record the model as “Unknown” only after thoroughly exploring all other avenues. Subsequently, we calibrate your instrument to your requested specifications or alternatively provide a “Data Only” calibration where no tolerances are applied, based on your preference.

While we strive to fulfill your exact requirements, we highly recommend avoiding a “Data Only” calibration. This type of calibration lacks a Statement of Compliance (In Tolerance or Out of Tolerance), resulting in the burden falling on you to consistently monitor the instrument’s performance and evaluate the calibration results. We understand the significant effort and time required for such tasks, diverting your focus from other critical responsibilities.

At International Process Solutions, we recognize these potential “quality blind spots” and have implemented robust precautions within our quality system to effectively address them on your behalf. When you choose us as your partner for calibration needs, you can trust that we understand the intricacies surrounding make and model identification and how it impacts your measurement processes.

However, if you opt for one of our competitors, uncertainties may arise regarding their ability to handle these blind spots effectively, potentially affecting your manufacturing or testing processes. Your business deserves the best possible solutions, and gaining a fresh perspective on these challenges is essential. Explore our website to access additional resources and white papers that offer insights into measurement risk and other important metrology concepts.

Remember, precise and reliable measurements are reliant on accurate instrument calibration, and identifying the make and model is a crucial factor in this process. At International Process Solutions, we are committed to quality and meticulous attention to detail that sets us apart. Choose us as your trusted calibration partner, and let us assist you in achieving precise, consistent, and reliable measurements every time.

When it comes to instrument calibration, International Process Solutions is the trusted partner you need to ensure the highest level of accuracy and reliability. Our commitment to delivering exceptional results, combined with our expertise in make and model identification, sets us apart from the competition. By choosing us, you can gain a competitive edge in your industry and elevate your measurement processes to new heights.

At International Process Solutions, we pride ourselves on our comprehensive knowledge of make and model identification in instrument calibration. We understand that the make and model information is not just superficial data, but rather a crucial element that directly influences the calibration process and the quality of your measurements. With our expertise, we can navigate the challenges posed by missing or hard-to-find model numbers, ensuring that your instruments are calibrated accurately and in accordance with your specific requirements.

The absence of a known model and specifications can raise concerns about setting appropriate calibration tolerances. But worry not, as International Process Solutions has the solution. Our experienced team will work closely with you as the equipment owner to determine the tolerances required by your unique processes. By collaborating with us, you can regain control over your quality system and ensure that the calibration tolerances align perfectly with your acceptance and rejection criteria. Alternatively, we can assist you in replacing the “Unknown” instrument with a known model and performance specifications, eliminating any ambiguity in your calibration process.

Arbitrarily assigning tolerances to instruments without accurate model information can lead to substantial risks to your quality system. By entrusting your calibration needs to International Process Solutions, you can avoid these pitfalls. We understand the significance of precise measurements and the impact they have on your manufacturing or testing processes. Our meticulous approach ensures that your instrument calibrations are carried out meticulously, aligning with your specific quality requirements and minimizing any potential blind spots that could compromise your operations.

At International Process Solutions, your satisfaction and success are our top priorities. We go above and beyond to ensure that our quality system is equipped to handle any challenges that may arise during the calibration process. By choosing us as your calibration partner, you can have peace of mind knowing that our dedicated team has implemented stringent precautions to address potential blind spots effectively. We are committed to delivering results that exceed your expectations, enabling you to focus on other critical aspects of your business without the need to constantly monitor calibration results.

Don’t allow uncertainty and blind spots to impede your measurement processes. Choose International Process Solutions as your trusted calibration partner and gain the advantage of our expertise, precision, and commitment to your success. With our unparalleled understanding of make and model identification, we will ensure that your instruments are calibrated accurately, providing you with reliable measurements that you can confidently rely on.

Contact International Process Solutions today and experience the difference our top-tier services can make in elevating your calibration processes and positioning your business at the forefront of your industry. Trust us to deliver exceptional results and help you achieve new levels of precision and reliability in your measurements. Together, let’s forge a path towards excellence and success!

Our clients know and love our flexibility. We work with startups, Fortune 500s, and everyone in-between.

We’re here for you at every stage of your growth, creating the exact solution you need. Reach out now – we’d love to help. Call Today 650-595-7890

No Comments