At International Process Solutions, we understand that precision and reliability are the foundation of every successful operation. Whether you work in pharmaceuticals, aerospace, medical devices, food production, or energy, the question of how often instruments should be calibrated is not one to take lightly. The accuracy of your instruments directly influences product quality, compliance, safety, and overall efficiency.

In this comprehensive guide, we will examine the critical factors that determine calibration intervals, industry-specific requirements, and best practices to ensure your instruments perform at peak reliability.

The Importance of Instrument Calibration

Calibration is more than just a regulatory requirement—it is the verification of accuracy against a recognized standard. Without consistent calibration, instruments may drift, leading to inaccurate readings, failed audits, product recalls, and costly downtime.

- Precision: Even the smallest deviations can affect test results, product batches, or safety standards.

- Compliance: Industries regulated by ISO, FDA, or GMP require documented calibration schedules.

- Operational Integrity: Calibration reduces variability, ensuring processes remain controlled and predictable.

General Guidelines for Calibration Frequency

While every situation is unique, most instruments should undergo calibration on a regular schedule. Here are widely accepted practices:

- Annually: The most common interval across industries for instruments used in stable environments.

- Semi-Annually: Recommended for critical applications, high-risk industries, or when precision is essential.

- Quarterly or Monthly: Used for instruments in extreme conditions or those with a history of drift.

Ultimately, the right interval depends on instrument type, application, regulatory standards, and operating environment.

Factors That Influence Calibration Intervals

Several variables dictate how often your instruments should be calibrated:

1. Instrument Type and Sensitivity

Highly sensitive devices such as pressure gauges, flow meters, and analytical balances typically require more frequent calibration than rugged field equipment.

2. Manufacturer Recommendations

Most manufacturers provide calibration guidelines. Following these ensures compliance with warranty terms and industry standards.

3. Frequency of Use

Instruments used daily or under heavy load should be calibrated more often than those used occasionally.

4. Environmental Conditions

Temperature fluctuations, humidity, vibration, and exposure to harsh chemicals accelerate instrument drift. Instruments in demanding environments need shorter calibration cycles.

5. Regulatory Requirements

Industries governed by ISO/IEC 17025, FDA, GMP, and NIST standards often mandate specific calibration intervals that cannot be ignored.

6. Historical Performance Data

Tracking how often an instrument fails or drifts outside tolerance helps establish a data-driven calibration schedule.

Industry-Specific Calibration Standards

Different industries have unique calibration requirements due to the risks associated with measurement inaccuracies.

Pharmaceutical and Biotechnology

- Must comply with FDA and GMP guidelines.

- Instruments such as balances, thermometers, and pH meters often require quarterly or semi-annual calibration.

- Audit trails and documentation are mandatory.

Medical Devices

- Calibration ensures patient safety and product integrity.

- Devices must align with ISO 13485 and FDA regulations.

- Critical instruments may require calibration every 3 to 6 months.

Food and Beverage Manufacturing

- Temperature, pressure, and flow sensors are crucial for food safety.

- Calibration cycles are typically every 6 to 12 months, depending on exposure to harsh environments.

Aerospace and Defense

- Precision is non-negotiable. Even a slight deviation can cause failure.

- Instruments are often calibrated monthly or quarterly, especially for flight-critical equipment.

Energy and Utilities

- Equipment must function reliably under high stress.

- Calibration frequency varies from annually to quarterly, depending on operating loads and environmental stress.

Consequences of Neglecting Calibration

Failure to calibrate instruments on time can have severe consequences:

- Product Recalls: Inaccurate measurements can result in non-compliant batches.

- Failed Audits: Lack of calibration documentation leads to regulatory penalties.

- Safety Hazards: Misreadings can jeopardize worker safety and consumer protection.

- Increased Costs: Downtime, rework, and waste escalate operational expenses.

Best Practices for Effective Calibration Management

Establishing an efficient calibration program ensures compliance and operational consistency.

1. Maintain a Calibration Schedule

Develop a calibration calendar tailored to each instrument’s role, usage, and history.

2. Use Accredited Calibration Services

Work with providers accredited by ISO/IEC 17025 to guarantee traceability and compliance.

3. Keep Detailed Records

Maintain documentation of calibration certificates, adjustments, and test results for every instrument.

4. Implement Risk-Based Calibration

Prioritize calibration frequency based on instrument criticality and potential impact on quality.

5. Conduct In-House Verifications

Routine checks between formal calibrations can identify early signs of drift.

The Role of Preventive Calibration

Rather than waiting for instruments to fail, preventive calibration ensures accuracy before problems arise. This proactive approach:

- Minimizes unexpected downtime.

- Extends instrument lifespan.

- Reduces risks of non-compliance.

- Improves long-term cost efficiency.

On-Site vs. Off-Site Calibration

Both methods have advantages depending on operational needs.

- On-Site Calibration:

- Fast turnaround.

- Minimal disruption to operations.

- Ideal for critical instruments.

- Off-Site Calibration:

- Allows for more extensive testing.

- Often used for highly sensitive or specialized equipment.

At International Process Solutions, we provide both on-site and laboratory calibration services to meet diverse industry needs.

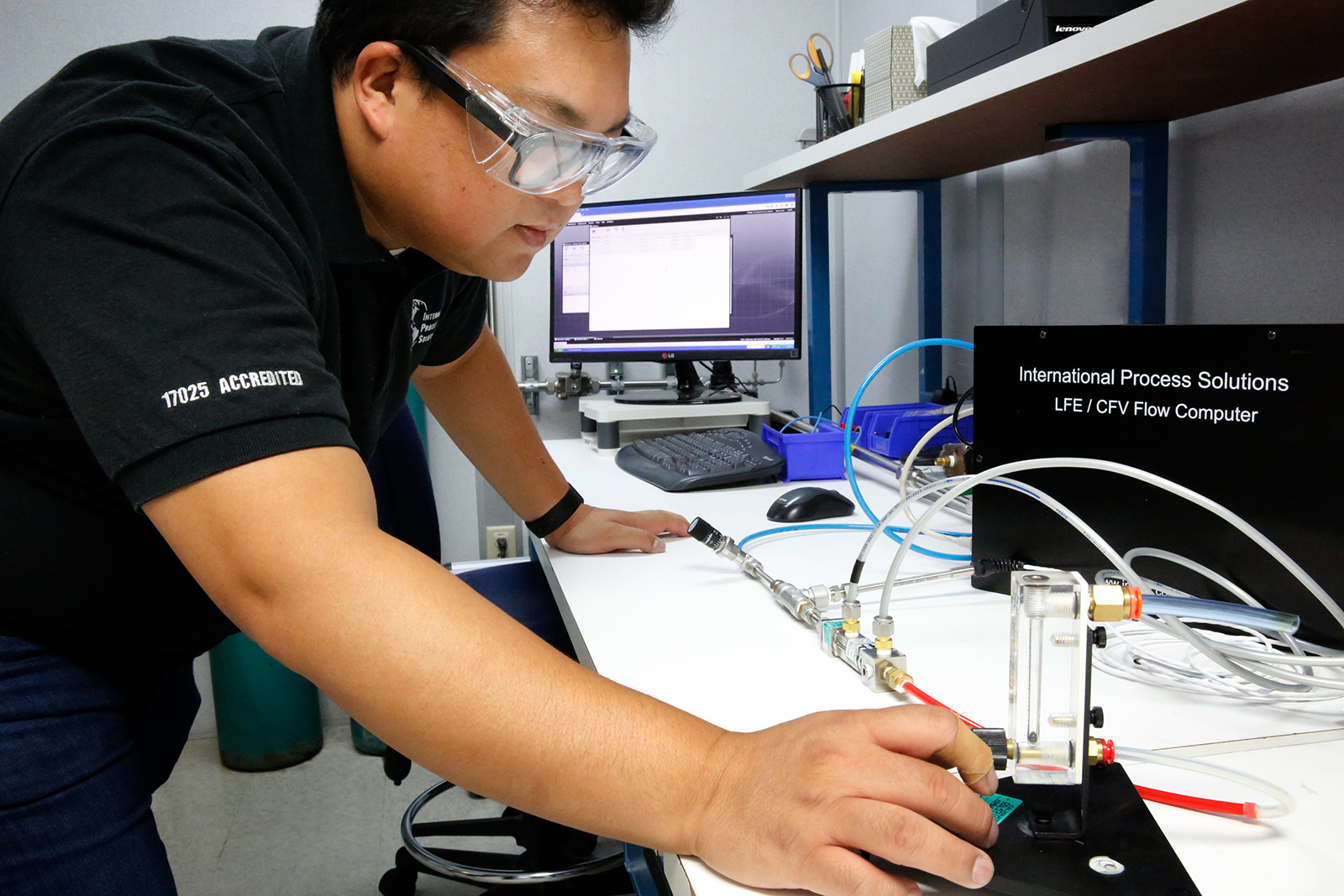

Why Choose International Process Solutions?

We deliver more than calibration—we deliver confidence. Our services include:

- ISO/IEC 17025 Accredited Calibration

- On-Site Calibration with 72-Hour Turnaround

- Comprehensive Documentation for Compliance

- Expert Technicians with Industry-Specific Knowledge

- Preventive Maintenance Programs

By combining technical expertise with fast, reliable service, we help organizations maintain compliance, accuracy, and operational efficiency.

Conclusion: Setting the Right Calibration Interval

There is no universal answer to how often instruments should be calibrated. The optimal interval depends on instrument type, environment, industry standards, and risk tolerance. However, adopting a structured calibration strategy ensures that your instruments remain accurate, compliant, and reliable.

At International Process Solutions, we work with our clients to design calibration schedules tailored to their specific needs. By doing so, we safeguard the integrity of their processes and help them maintain the highest standards of quality and safety.

International Process Solutions is your trusted partner for precision calibration services. Contact us today to develop a calibration program that guarantees compliance and protects the integrity of your operations.

REQUEST A QUOTE