Ensuring full compliance with OSHA and FDA regulations is not optional—it is a fundamental responsibility for any organization operating in regulated environments. At the core of meeting these stringent standards lies one essential practice: precise, consistent, and documented calibration. In industries where safety, product integrity, and regulatory adherence define success, equipment calibration becomes the backbone of operational reliability. In this comprehensive guide, we delve into how proper calibration supports compliance, reduces risk, protects workers, and strengthens quality management systems.

Why Calibration Is Critical for OSHA and FDA Compliance

Calibration directly impacts the accuracy and reliability of the instruments used in manufacturing, laboratories, pharmaceuticals, biotechnology, food production, aviation, chemical processing, and healthcare. When equipment is not calibrated, even minor inaccuracies can lead to serious safety hazards, compromised product quality, and immediate regulatory violations.

Both OSHA and the FDA mandate that companies maintain measurement equipment in proper working condition, ensuring that all readings and recorded data reflect true performance. Without routine calibration, the integrity of safety systems, testing procedures, environmental controls, and product specifications comes into question—putting your entire operation at risk.

OSHA Requirements: Calibration as a Safety Imperative

Ensuring Accurate Environmental Monitoring

OSHA regulations require employers to manage worker exposure to hazardous conditions such as:

- Chemical vapors

- Dust and particulates

- Noise

- Temperature extremes

- Radiation

- Inadequate ventilation

To measure these hazards accurately, facilities rely on equipment such as gas detectors, sound level meters, air quality monitors, temperature sensors, and more. Routine calibration ensures these instruments provide true readings so corrective actions can be taken before workers face harm.

Calibration for Safety Devices and Control Systems

Critical safety devices require precise calibration to function effectively:

- Pressure relief valves

- Emergency shutdown systems

- Load indicators

- Machine guards

- Lockout/tagout verification devices

If these systems fail due to calibration drift, serious injuries or fatal incidents can occur. OSHA penalties for uncalibrated or malfunctioning safety systems can be significant, especially if an accident results.

FDA Compliance: Calibration as a Quality and Documentation Requirement

Accurate Measurement in Regulated Industries

The FDA enforces strict guidelines for measuring equipment in:

- Pharmaceutical manufacturing

- Biotechnology labs

- Medical device production

- Food and beverage processing

- Clinical laboratories

Every measurement that affects identity, strength, purity, or quality must be accurate. This requirement can only be met with properly calibrated equipment.

21 CFR Part 11 and Part 820: Calibration Documentation Rules

FDA inspections often focus heavily on calibration records. To remain compliant, companies must maintain:

- Calibration schedules

- Instrument history files

- Traceable calibration certificates

- Out-of-tolerance (OOT) reports

- Corrective and preventive actions (CAPA)

- Documentation of standards used during calibration

A single missing or incomplete calibration record can lead to audit findings, warning letters, or shutdowns.

Risk Reduction Through Calibration Controls

FDA frameworks emphasize risk-based quality systems. Proper calibration supports this by ensuring:

- Accurate batch documentation

- Consistent test results

- Reliable equipment performance

- Traceability from raw materials to finished products

Calibration directly supports Good Manufacturing Practices (GMP), Good Laboratory Practices (GLP), and Good Clinical Practices (GCP).

How Calibration Reduces Business Risk and Liability

Prevents Costly Product Errors and Recalls

A slight deviation in measurement tools can lead to:

- Incorrect ingredient dosing

- Failure to meet product specifications

- Manufacturing inconsistencies

- Cross-contamination risks

- Failed sterility or potency tests

These errors can render entire batches unusable, resulting in millions of dollars lost—and, more critically, compliance violations.

Protects Workers From Unsafe Conditions

Calibration ensures that workers receive accurate information about their environment, enabling management to:

- Prevent toxic exposure

- Maintain ergonomic safety

- Control temperature and humidity

- Reduce equipment failures

- Avoid overloading machinery

With accurate data, environments can be kept safe and compliant.

Minimizes Legal and Regulatory Exposure

Uncalibrated equipment is a documented violation of both OSHA and FDA guidelines. Violations can lead to:

- Significant financial penalties

- Warning letters or citations

- Production stoppages

- Lawsuits from employees or consumers

- Loss of certifications or licenses

Routine calibration is far less expensive than dealing with the consequences of noncompliance.

What Instruments Must Be Calibrated for OSHA and FDA Compliance?

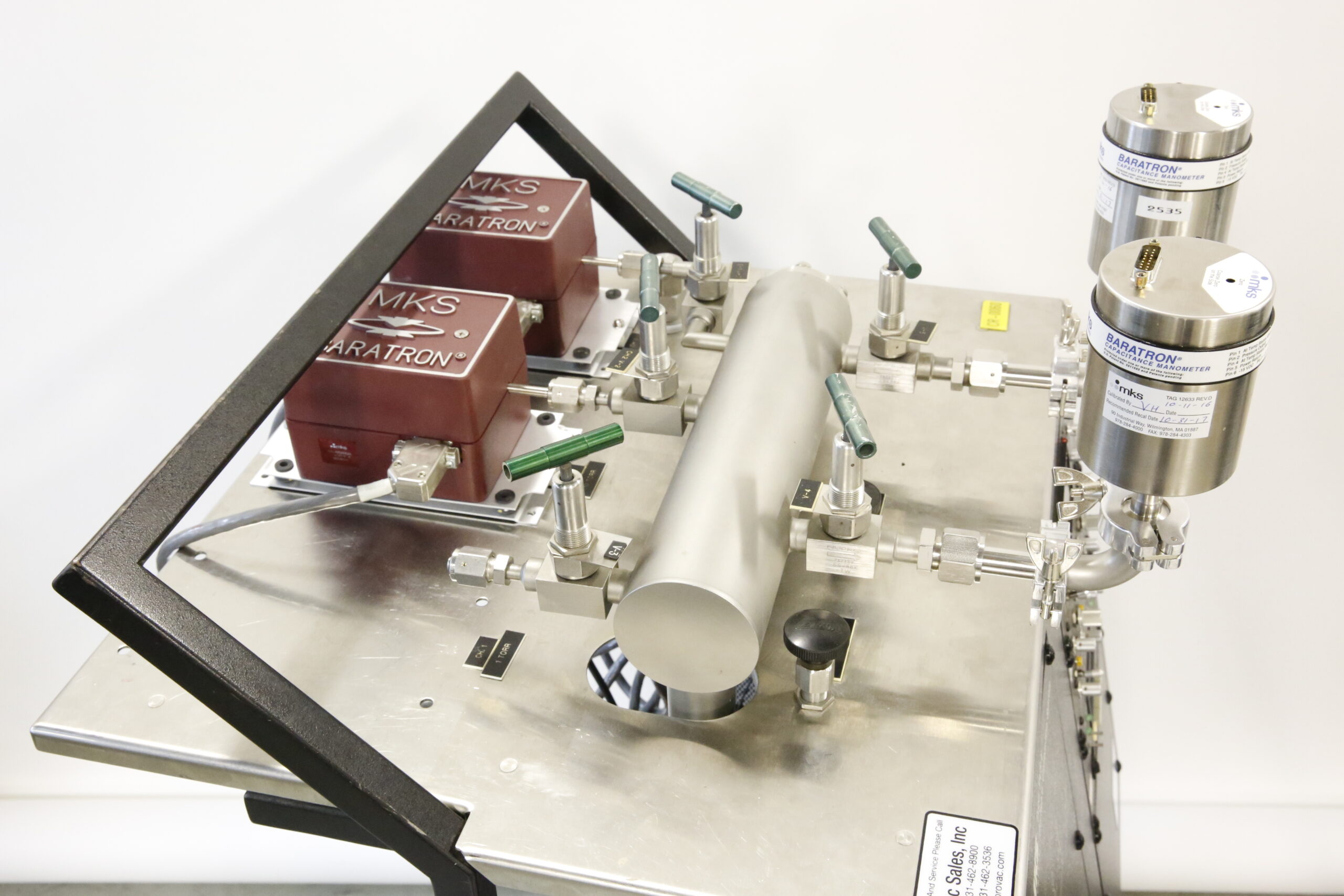

Some of the most common instruments requiring routine calibration include:

- Pressure gauges

- Balances and scales

- Pipettes

- Thermometers and temperature sensors

- pH meters

- Hygrometers

- Gas detectors

- Airflow meters

- Torque wrenches

- Flow meters

- Thermocyclers

- Spectrophotometers

- Weighing systems

- Electrical testing equipment

- Autoclaves and sterilization equipment

Any device used to measure, monitor, control, test, or record data must be included in your calibration program.

Establishing a Calibration Program That Meets OSHA and FDA Standards

Inventory and Classification

Start with a full inventory of all measurement devices. Classify equipment based on:

- Calibration frequency

- Criticality to safety or compliance

- Required accuracy and tolerances

- Manufacturer recommendations

Use of Accredited Calibration Providers

To maintain traceability and credibility, companies benefit from using ISO/IEC 17025 accredited calibration labs. Accreditation ensures:

- Use of validated procedures

- Traceability to NIST standards

- Highly trained technicians

- Compliant documentation

Set Calibration Intervals Based on Risk

Intervals may be determined by:

- Equipment usage

- Environmental conditions

- Manufacturer recommendations

- Historical performance

- Regulatory requirements

Document Everything

Your calibration program must include:

- Calibration certificates

- Equipment labels

- Calibration logs

- Recall and notification systems

- Nonconforming equipment reports

A well-documented system is essential during audits.

Consequences of Failing to Maintain Calibration Compliance

Failure to comply with OSHA or FDA calibration standards can lead to:

- Injuries or fatalities

- Product contamination

- Regulatory shutdowns

- Hefty fines

- Loss of customer confidence

- Damaged brand reputation

- Product recalls

- Legal actions

In regulated environments, even minor inaccuracies can lead to catastrophic outcomes. Calibration is a safeguard that cannot be overlooked.

The Competitive Advantages of a Robust Calibration Program

Organizations that prioritize calibration benefit from:

- Higher product quality

- More reliable data

- Reduced downtime

- Stronger audit readiness

- Improved worker safety

- Greater operational efficiency

- Fewer equipment failures

- Enhanced customer trust

When calibration becomes an integral part of your operational culture, compliance follows naturally.

Final Thoughts

OSHA and FDA compliance begins with one foundational practice: accurate, traceable, and well-documented calibration. Whether your facility manufactures pharmaceuticals, processes food, conducts lab testing, or operates industrial machinery, calibration ensures safety, quality, and regulatory integrity at every step. By prioritizing calibration, you protect your team, safeguard your products, and strengthen your organization’s reputation in highly regulated industries.